Introduction

A main producer of horticultural containers in North America manufactures and distributes plastic trays and pots, and various other growing containers.

Printing and labelling services are available to ensure the containers of this company’s customers get noted.

For the decoration by printing 2 printers of the VanDam brand are used, from 2000 and 2007, respectively.

Problem

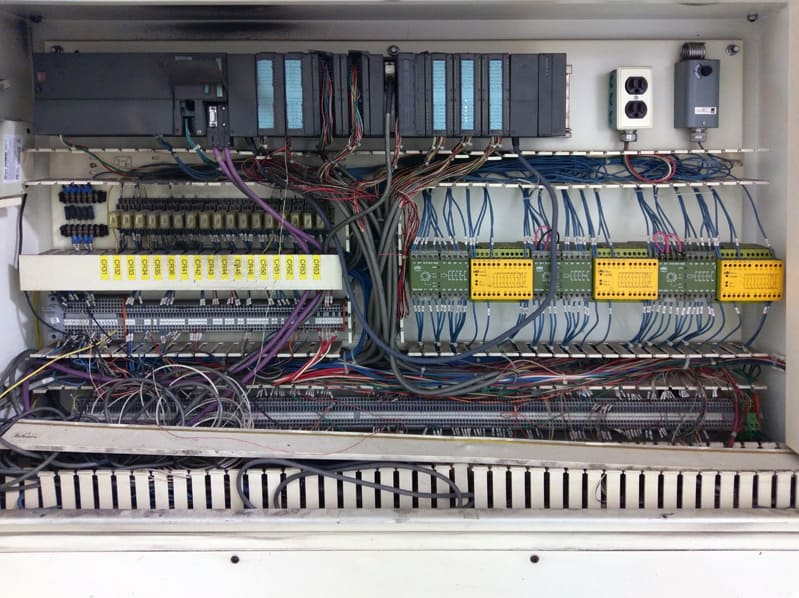

The printers increasingly showed downtime issues, due to the age of their control systems.

After many years of production control system components became unreliable, which regularly forced the machines to a standstill.

In the course of time, replacement parts were getting harder to find, as was the knowledge to maintain the control systems.

In addition, software support by the OEM was no longer available.

The result was that the company’s pole position in the North American horticultural segment became under threat.

Solution

We started with an inspection visit on location to map the current hardware, functionalities and known issues.

The next step was to get in touch with the company’s personnel, to list their requirements for existing and new functionalities.

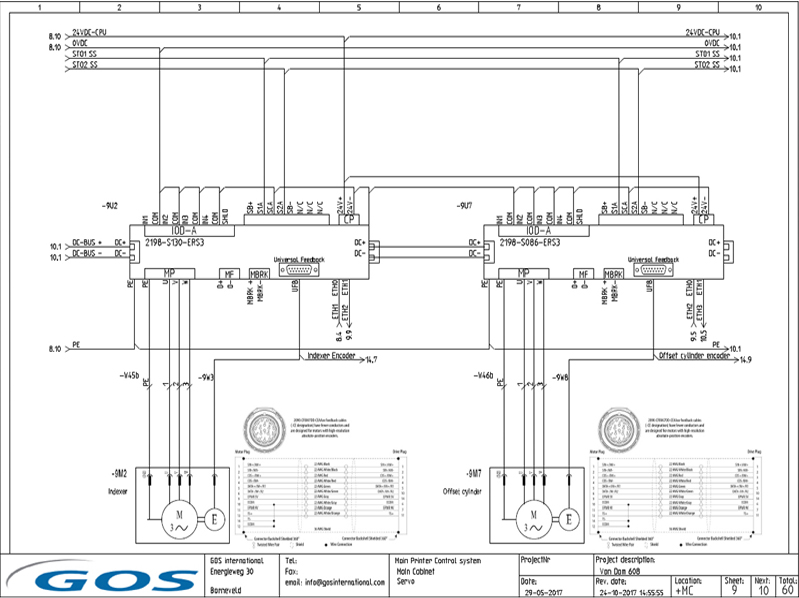

These results were merged into a new hardware and software design for new control systems of the 2 machines.

Thanks to the data collected at an earlier stage, software programming and construction of the control cabinets could take place at GOS, without the presence of the machines. Upon completion, the new systems were shipped to the printing facility for installation and commissioning.

Result

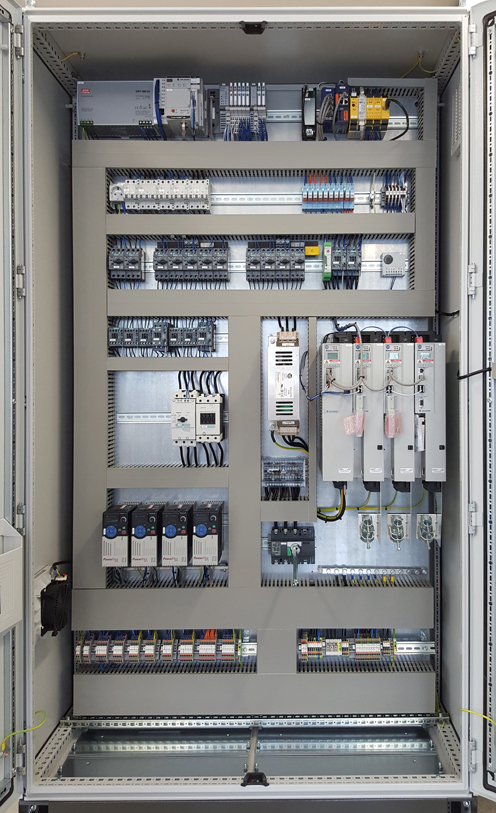

Both printing machines were connected to a new control cabinet, containing:

- an Allen Bradley PLC

- a Pilz safety system

- Allen Bradley AC drives

- Allen Bradley servo drives

- an eWon remote connectivity unit

- an Allen Bradley touch panel with GOS operating software

In addition to a new main cabinet, the feeder and the restacker of each machine was equipped with a remote I/O (RIO) station. The original servo motors were replaced; the original AC motors could stay, as they were still in good working condition.

The new control system has decreased unscheduled down time considerably. This resulted in an improvement of the OEE of both machines of 5%.

Next to the improvement of the OEE, the upgrade has restored the maintainability of the control system. The Allen Bradley hardware that was used, will be available for more than 10 years, and an internet connection facilitates remote diagnostics.

Next

New functionality can be added to further improve the OEE of the decoration process, like adding sensors for predictive maintenance, or connection to the factory’s data network (IIoT)